Why Your Sample Was Perfect, But Production Failed?

The nightmare of every brand owner: The bulk order doesn't match the golden sample. Why does this happen, and how do we prevent it?

Direct insights from the factory floor. We help you make better sourcing decisions.

The nightmare of every brand owner: The bulk order doesn't match the golden sample. Why does this happen, and how do we prevent it?

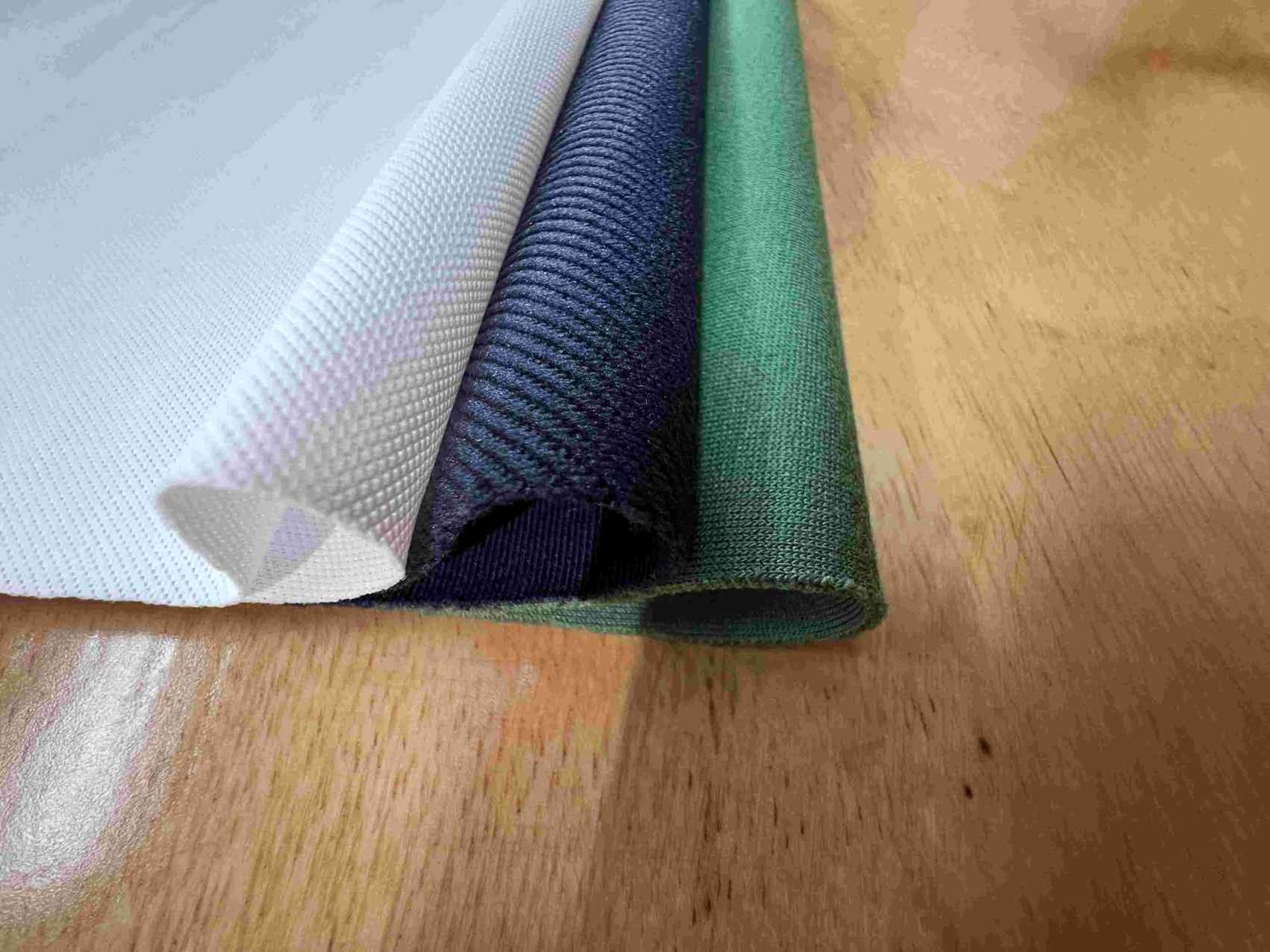

Cheap factories often cut costs using low-grade cotton, no pre-shrinking, and unstable printing ink. The result is high return rates.

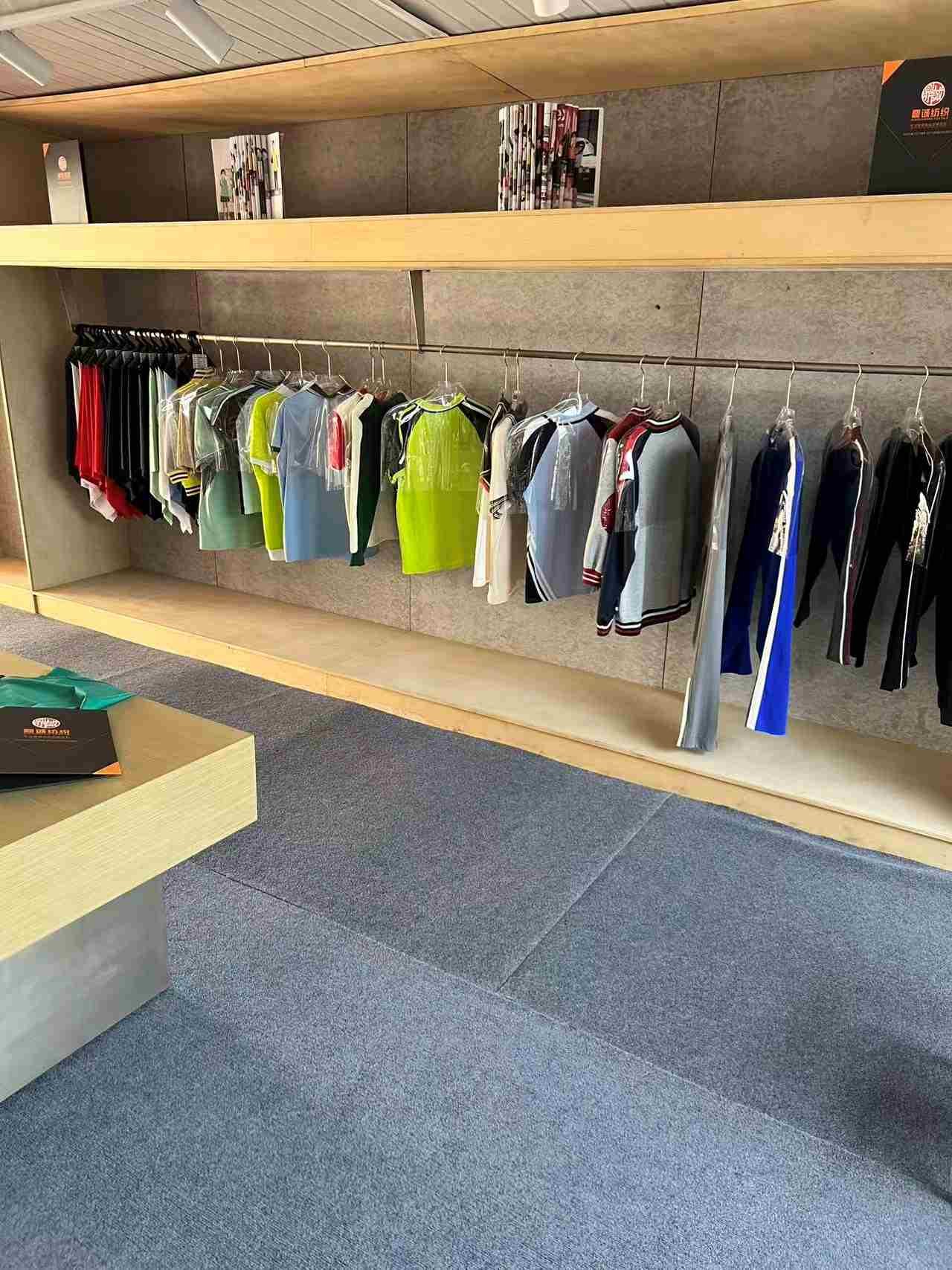

Big factories ignore small orders. Small workshops lack consistency. That’s why startups struggle.

300 GSM T-shirts feel heavier, more structured, and are preferred by premium streetwear brands. But is it right for you?

Sourcing from China? Don't send money until you verify these 4 things. A guide to safe B2B sourcing.

AQL 2.5 is the most widely accepted quality inspection standard. Yet many factories claim to follow it without real execution.

Choosing the right printing method leads to cracking prints and unhappy customers. We compare the top 3 methods.

Fabric shrinkage is a top reason for returns. Cheap factories skip pre-shrinking to save cost. Premium brands don't.

Private label is more than putting your logo on a T-shirt. Tags, wash labels, and packaging all affect how customers perceive your brand.

Many brands fail not because of design, but because their factory can’t scale with them. Scaling works only when quality stays consistent.